Most alloys used in aerospace applications are both difficult to machine and expensive (inconel, waspaloy, hastelloy, cobalt, stainless steel, etc.). One of the ways to keep costs low is to minimize machining time and by starting with near net shapes. The utilization of forgings and castings are one way - and using abrasive waterjets is another. Abrasive water jet cutting technology allows one to create near net shape blanks that can be subsequently machined for lessor costs - abrasive waterjets offer one the luxury of metal cutting near to the finish size so that CNC machining and associated tool wear is that much less. Depending on the size of the workpiece and the size of the raw material used, you can fit more than one part in the workpiece thereby increasing the productivity rate.

For some parts with open tolerances Waterjet cutting machine are highly efficient, especially when used in combination with a ideal clamping fixture and a correctly positioned high-pressure stream of water mixed with garnet (sand) traveling at velocities approaching four times the speed of sound. For some parts with slightly more ‘open tolerances, an abrasive waterjet can sometimes hold finish tolerances and thus no subsequent machining operations are required. For parts made from plate stock, high-pressure waterjet cutting machines can run unmanned and require only periodic inspection to ensure all dimensions and features are in conformance.

Waterjets operate using extremely high-pressure pumps and can cut literally any material - from glass, marble and stone to metal and plastics – completely burr-free and without introducing any thermal distortion or heat-affected zones, making them a preferable option when working with materials that are sensitive to heat or stress.

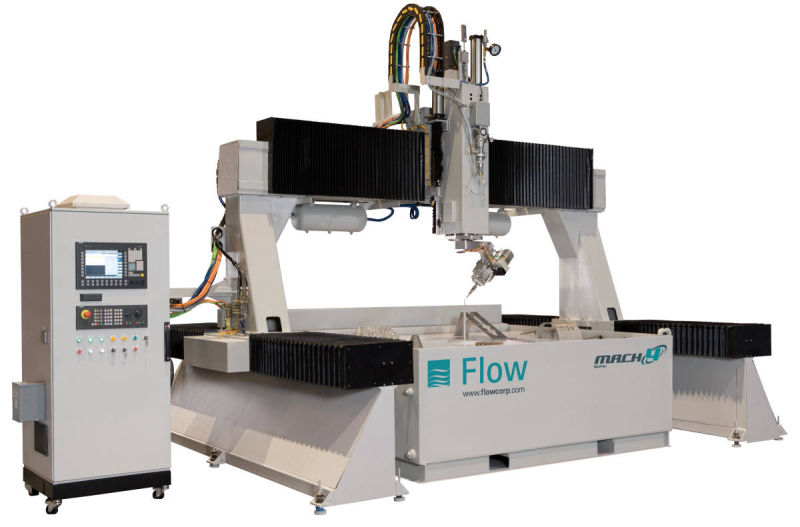

Slabe Machine waterjet department contains both OMAX machines as well as the newest 94,000 PSI HyperJet FLOW machines with articulating 3D cutting heads, which enables us to cut complex geometries from either plate stock or fixtured workpieces without any of the taper characteristic of 'traditional waterjets' giving us the ultimate accuracy, speed and flexibility.